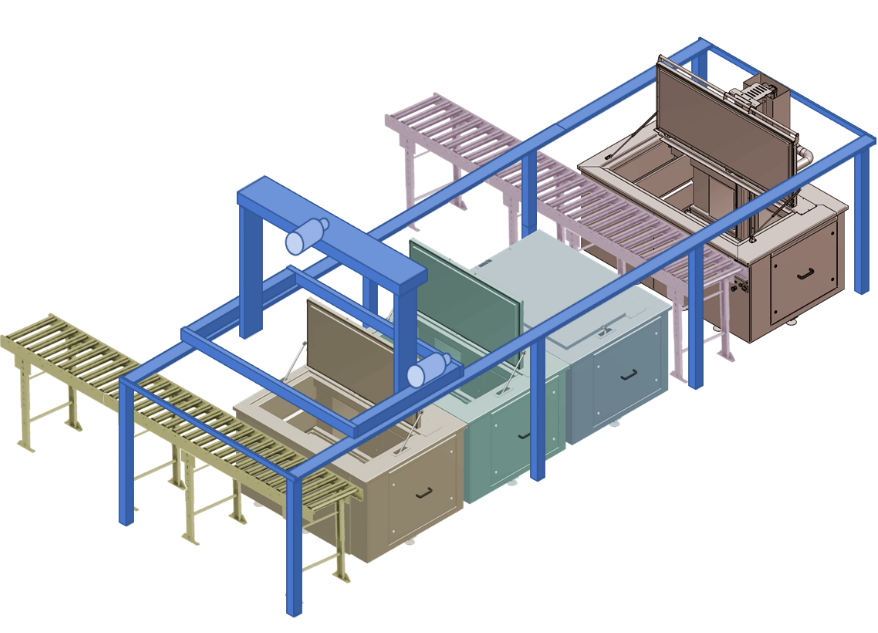

Special automatic multistage equipment to obtain the best performance for the cleaning and degreasing of axlebox bearings

UltraTecno has develop a special multistage equipment with automatization for the manipulation of the axlebox bearings. The railway industry is characterised for the need of regular maintenance in terms of the cleaning and degreasing of axlebox bearings. With this new system, lots of costs are minimize, such as savings in time, water, energy consumption, and labour, as both the cleaning and manipulation process are automatized. You will arrive at the optimization that the railway sector maintenance implies.

It is an innovative way to expand and develop the railway maintenance. We are conscious of the heavy work that carries the cleaning and degreasing of axlebox bearings, thus with our 28kHz technology railway maintenance work will be an easy and effective job to do. Such technology facilitates and completely eliminates that the grease that is so difficult to be removed.

Some examples of axlebox bearings that are design:

- Ball bearings

- Spherical roller bearings

- Tapered roller bearings

- Cylindrical roller bearings

- Needle roller bearings

Adapted for the railway industry: Automatic multistage equipment consisting in 4 tanks:

- Ultrasonic cleaning tank.

- Cold/hot rinsing tank

- Passivation tank

- Drying tank