Do you rewind motors in your workshop? Then ultrasonic cleaning is the best way to increase your productivity and efficiency for electric motors repair.

The employ of ultrasonic cleaning equipment in your workshop increases the quality of your cleaning tasks and speeds up the processes compared with conventional cleaning techniques.

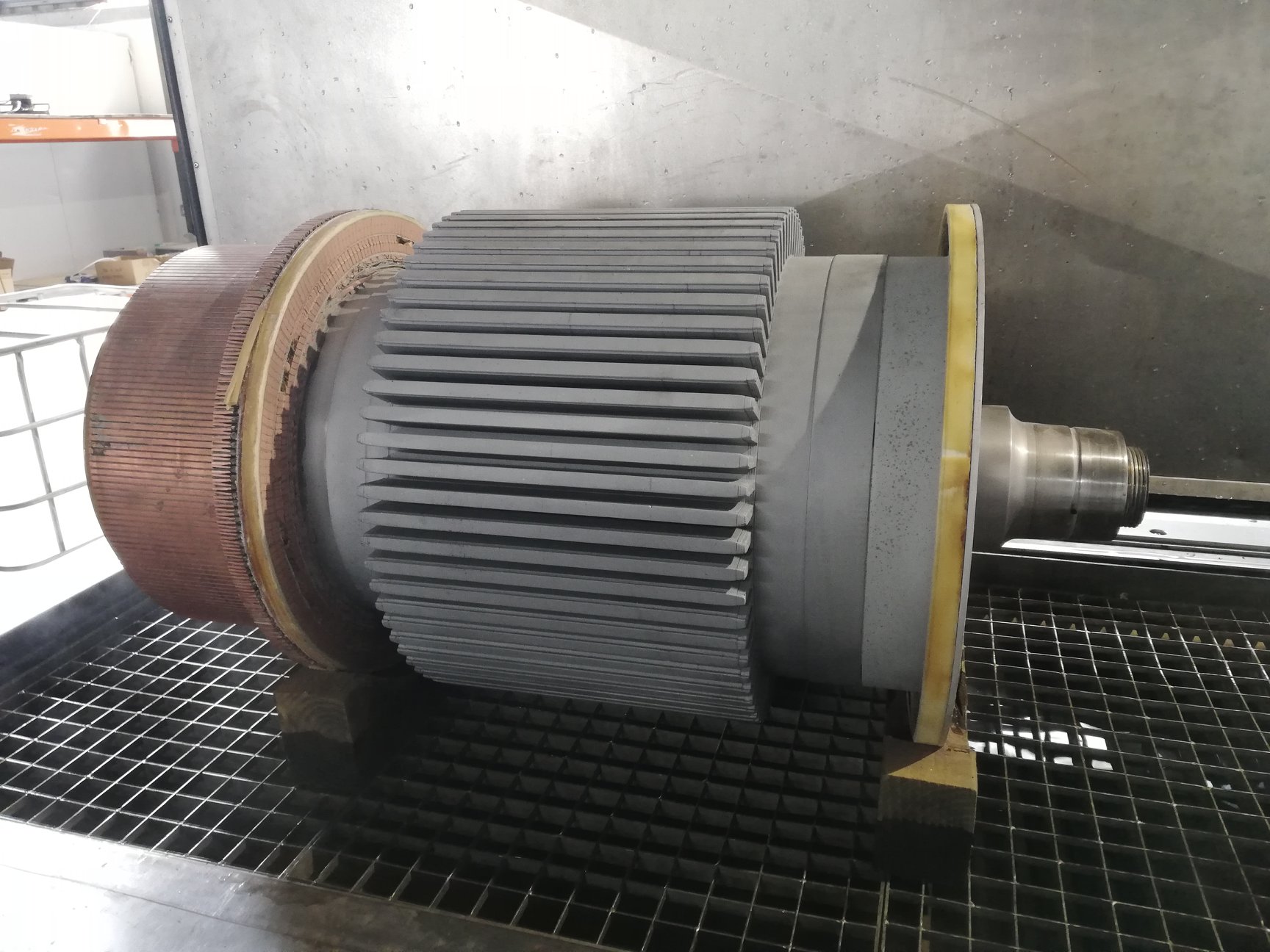

If your business is repair and maintenance of industrial electric motors and generators, you need to know that applications suitable for ultrasonic cleaning include components such as armatures, wound rotors, stators, induction rotors, clutch and brake coils, synchronous rotors, motor parts, heat exchangers, field frames, or synchronous coils in the electric motor repair service center.

As an example of ultrasonic cleaning of electric motor you can see on the pictures bellow.

As our customer Advanced Component Cleaning from Ireland states:

“These industrial motors are stripped back and prepared for “rewinding”. The biggest challenge for many customers is to the stripping off the resin but between using ultrasonic cleaning and a third party that glass blasted the rotor we got it back to new and ready for being rebuilt!”

Ultrasonic cleaning equipments give to workshops effectiveness in repair for industrial electric motor and generators because make a faster, homogeneous and better repair job with improvements in productivity, final product quality and safety for the shop operators.

If you need any additional information about ultrasonic cleaning before rewinding electrical motor do not hesitate to let us know.