Ultrasonic Cleaning brings benefits to many industries. Especially in the food industry are appreciated the specific characteristics of ultrasonic cleaning; as homogenous cleaning in the complex shapes or labor free operation.

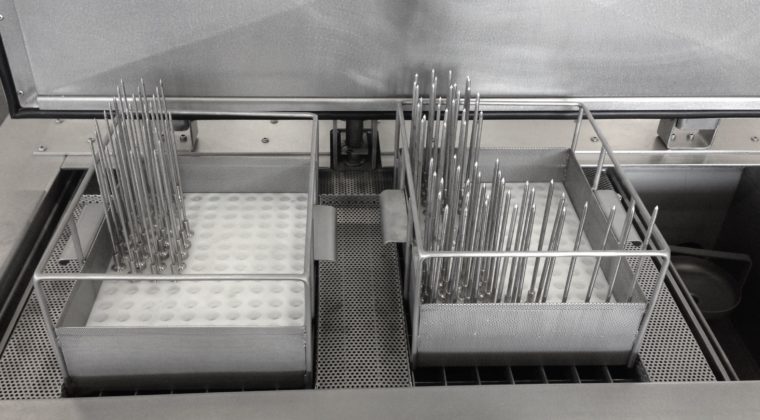

Ultratecno ultrasonic cleaning equipment complies with the strict hygiene and safety norms of food industry. As an example we provide this case study for the cleaning and sterilization of stainless steel needles which are used in the meet processing equipment.

This stainless steel needles are hollow and during the meat processing they can be obstructed by proteins. For the correct use of the food industry machinery is necessary regular maintenance and cleaning of these key components.

As confirmed by a laboratory test and by daily use in the industry with following cleaning parameters, ultrasonic cleaning for meat processing equipment is a perfect solution:

- Temperature of ultrasonic bath: 70ºC

- Ultrasonic cleaning time: 30 minutes

- Concentration of alkaline detergent in water 3%

With this ultrasound process is achieved that concentrated or isolated hydrolyzed proteins of animal or vegetable origin are properly detached from the inner walls of the needles. And as confirmed by laboratory tests there are no microorganisms present on the washed needles. The washed components are practically sterile.

For more information about the ultrasonic cleaning in the food industry do not hesitate to contact info@ultratecno.es