For Engine Rebuilder Cleaning heads and blocks can be a challenge for a number of reasons.

The castings have complex geometries where both, interior and exterior surfaces have to be cleaned. There are different type of the dirt including cover of rust, scale or sediment on the surface, sludge and varnish deposit in the oil lines and hard carbon layers in the combustion chambers.

Cleaning is a costly operation in engine rebuilding process with very low added value. To calculate the cost of the cleaning itself you have to include:

- Labor cost

- Power consumption

- Water consumption

- Detergent cost

- Waste treatment

- Machinery cost

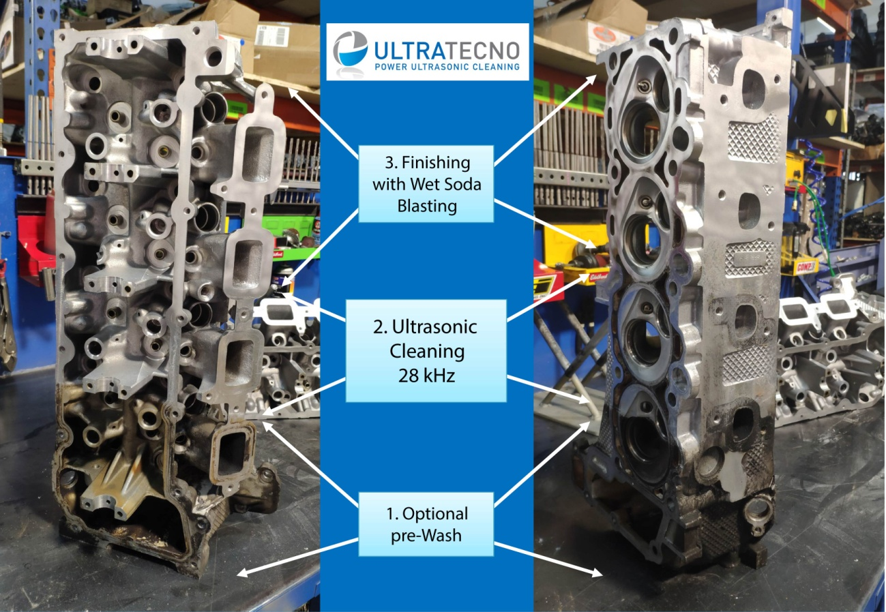

UltraTecno has a great experience with Cylinder Heads and Blocks cleaning. We know that there is no universal solution for every workshop and for all parts but during the years we have collected lot of tips and tricks. And this is the recommended cleaning procedure designed by our customers:

- Prewash: Only extremely dirty parts should be prewashed in the hot dip tank with alkaline degreased.

- Ultrasonic cleaning: 90% of the cleaning is done by ultrasound cleaning process – 28khz synchronized ultrasonic technology and oscillation movement of the platform lift is must. Our ACM – Series was especially developed for this application.

- Wet soda blasting: Final finish with wet soda blasting, for aesthetic reasons.

For more general information regarding the Cleaning Cylinder Heads and Blocks we recommend an interesting article which compares different cleaning techniques.