Complete thermal insulation

Our equipment is completely insulated (including the cover) to avoid heat losses and to ensure quick attainment of the required temperature.

Laminar flow Separation System (LFSS)

After dirt and grease are extracted from the parts, they must be removed from the main barrel. Our exclusive Laminar Flow Separation System (LFSS) takes floating grease to an auxiliary tank where it can be easily removed.

Complete recirculation of cleaning liquid

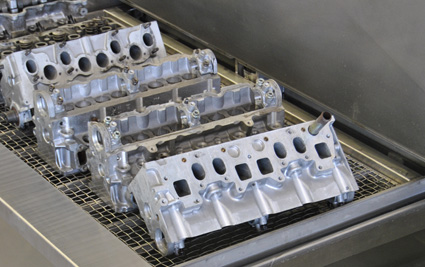

The parts to be cleaned are shaken inside the deposit during the automotive engine cleaning process so the liquid may agitated inside the tank. This process considerably improves the results.

Frequent flushings

We have eight different frequent flushings that may be configured to improve performance and to achieve better distribution of the cavitation field with a bandwidth up to 3%.

Programmable automaton and Touch-Screen

Our equipment includes a Programmable Automaton (PLC) for process control.

The user controls the process through a colour touch-screen in various languages. It can be activated in the automatic mode which does not require the presence of the operator during the automotive engine cleaning process with ultrasound.

Elevator tray

The parts are easily placed in the cleaning tray.

The tray is activated pneumatically/hydraulically and can manipulate operation loads up to 2,100 kg or higher.

100% Stainless Steel Construction

All our machines are completely built in stainless steel. Our thorough quality control systems ensure the non-existence of leaks in weldings or mechanical unions.

Stop & Go

This operation mode facilitates the sloughing of specific types of dirt with high adherence levels.

Our system cleans automotive engines in a quick, safe and inexpensive manner, and assures that the smallest and most delicate parts are always ready.